The

revolutionary

PUMP

MODULE

eliminates

repair

and

maintenance

hassles

of

marine

toilets.

Owners

and

charter

crew

won’t

have

to

spend

hours

replacing

a

$2

rubber

seal.

No

more

puddles

of

sewage

on

the

toilet

floor.

The

PUMP

MODULE

includes

all

serviceable

parts

in

a

single

module

and

it’s

as

easy

and

quick

to

replace

as

a

printer

cartridge.

The

PUMP

MODULE

solution

is

available

for

both

manual

and

electrical

toilets.

Benefits to Users

Available for both manual and electrical toilets

- The Manual PUMP MODULE includes the hand pump and all valves, gaskets and seals.

- The Electric PUMP MODULE includes the macerator and flushing pumps and valves.

- The cartridge snaps into a docking base that contains hose connections and pump motor(s). Hose connections don’t have to be undone for replacing a cartridge.

Clogged toilets fixed in minutes

- No more need to wait for plumbers. Unlatch the old PUMP MODULE and replace it with a spare. Snap the spill cover on the old cartridge and dispose it or recycle.

No more unhygienic leaks

- Servicing existing marine toilets results in messy, unhygienic leaks, which are practically unavoidable. Using a PUMP MODULE and its patented drain solution eliminates this unpleasant problem. The hose connections don’t have to be undone.

Cost savings

- Save the ever increasing costs of professional plumbers. Save the costs of your own time. If you calculate the costs of servicemen and your own time maintaining and cleaning up, how much is your marine toilet costing you yearly?

Yearly service simplified

- Enjoy the smooth, freshly lubricated, perfect operation of a new toilet for the price of a new PUMP MODULE. All valves, pistons and other serviceable parts are replaced when you snap in a new cartridge, so you won’t have to replace them one by one when they gradually fail.

Problem free charter

- Clogged toilets can ruin a sailing holiday. Charter boats can provide several PUMP MODULEs as standard spares. This eliminates wasted time for cruisers and logistic problems for charter companies. The cost of used cartridges is simply deduced from the deposit.

Compatible with existing toilet designs

- Existing marine toilets can easily be converted to the new PUMP MODULE solution. The existing toilet bowl can be reused and the existing hoses connected to the docking base.

Benefits to Manufacturer

Disruptive technology

- The patented PUMP MODULE takes marine toilets to the 21st century. Repair is expensive today and products are normally replaced instead of repaired. Plumbers are becoming hard to find and expensive. It is unrealistic to expect people to have the skills and interest to regularly take apart their marine toilets for repair and maintenance. For charter companies marine toilets are a major headache. A toilet that solves these problems will seriously hurt competitors.

International patent protection

- International patents were filed on February 16, 2010 EUR 10153745.4 “Toilet pump module system” and on April 13, 2010 EUR 10159783.9 “Plug-n motor connector”. These will be followed up with filing with the US Patent Office and other national patent offices within the 12 month window of priority, in accordance with international patent conventions. The patents will prevent competitors from copying the PUMP MODULE solution.

Clients spend their money on spares instead of plumbers.

- It is expected that boat owners will prefer to spend their money on buying spares instead of paying plumbers or spending their own leisure time with this very unpopular job.

- Repair costs are converted into extra income for the Manufacturer.

Ongoing profits

- The Holy Grail of all manufacturers is ongoing sales to existing clients. Printer companies make most of their profits from the sale of cartridges. The PUMP MODULE will achieve the same for the marine toilet Manufacturer.

- Conversion kits can be offered for existing competitor products as well, so that they become suitable for the use of PUMP MODULEs.

Production runs multiplied

- It is expected that most users will replace their PUMP MODULE every year. Considering that people today don’t replace their pumps more often than every 6-10 years, selling pump modules will multiply pump production volumes, which ideally suits mass production.

Impressive projected revenues

- There were 12.9 million recreational boats registered in the United States in 2001 according to the U.S. Coast Guard (no newer data available). Of course the majority of these don’t have fixed toilets. But even 5% of the market is over 600,000 boats. Charter boats would probably use up several PUMP MODULEs every year, other boats might use only one every 1-2 years. Assuming that a cartridge costs $100 the expected cartridge sales is expected to reach $50M per year within a few years in the US market.

Detailed design and working model available

- Detailed design concepts by experienced engineers have been created for the PUMP MODULE system, including solutions for fast, leak-proof pipe coupling, engine shaft coupling and cartridge latching.

The patent includes a simple solution to drain the bowl content without any leak to the floor and without any drainage taps.

Technical Implementation

The objective of the proposed technical solution is a toilet pump that can be replaced without tools and leak.

A preliminary design is presented here that can be used by the Manufacturer to develop production models.

The drawings are for illustration purpose only and they are not to scale.

The principle of both the Manual and Electrical Pump module is protected by international patents.

Technical Implementation of Manual Pump module

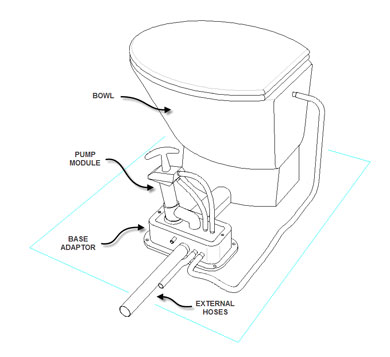

The implementation is based on a universal, disposable Pump module – a complete hand pump - that plugs and latches into a permanently installed Base Adaptor. A Manufacturer might decide to supply Base Adaptor kits to fit various popular marine toilets on the market or sell it only for its own brands. Once the Base Adaptor is fitted, the toilet is ready to use with universal, disposable Pump modules.

An improved implementation of the Base Adaptor would require the redesign of the existing plastic moulding that connects the toilet bowl to the pump. The Base Adaptor would become part of the plastic moulding.

The description below is based on the popular Jabsco manual toilet assembly (model 29090-3000 or 29120-3000). The Base Adaptor bolts onto the existing surface where currently the pump is fitted.

Pump Module

The existing Jabsco Pump Assembly includes the standard Jabsco Base Valve Gasket and Joker Valve. The new Pump module can be designed using the existing pump assembly and modifying the pump body plastic mould by adding the required pump adaptor fixtures described below.

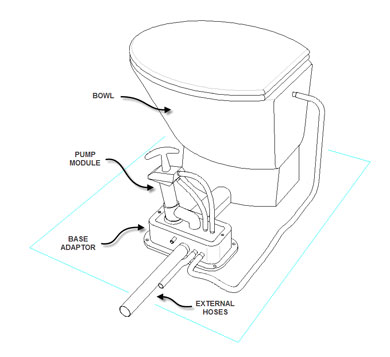

The Pump module has four pipe fittings extending out of the bottom: wastewater in, wastewater out, flush water in and flush water out. Each pipe fitting includes two o-rings to provide a double seal when the Pump module is inserted into the Base Adaptor. The pipe o-rings are mounted on the Pump module rather than the Base Adaptor so that new, replacement seals between the adaptors are provided every time the cartridge is replaced.

The Pump module includes two quarter turn, quick release fasteners to securely fasten the Pump module to the Base Adaptor. A coin or screw driver is used to release these fasteners to avoid accidental release of the Pump module from the base. A green “engaged” or a red “disengaged” indicator is displayed by the fasteners to give a clear indication that the Pump module is installed and latched correctly.

Base Adaptor

The Base Adaptor becomes part of the redesigned wastewater feed coming from below the bowl. The Base Adaptor and the wastewater feed don’t include any moving parts, valves or seals, so do not need to be replaced or maintained.

The Base Adaptor has four pipe sockets on the top which accept the four pipes protruding from the bottom of the Pump module. Each pipe socket includes a bevelled top to guide the Pump module pipes and their o-rings smoothly into the Base Adaptor.

The Base Adaptor provides the following connections for the pipe fittings from the Pump module:

- Wastewater In : connects to the toilet bowl

- Wastewater Out : connects to the discharge hose via a discharge pipe fitting. The discharge hose is connected to this discharge pipe fitting during initial installation and remains attached at all time, even when the Pump module is being replaced.

- Flush Water In: connects to the water inlet hose via a water inlet pipe fitting. The water inlet hose is connected to this inlet pipe fitting during initial installation and remains attached at all times, even when the Pump module is being replaced.

- Flush Water Out: connects from the bottom of the Base Adaptor to the top/back of the bowl via a flexible hose.

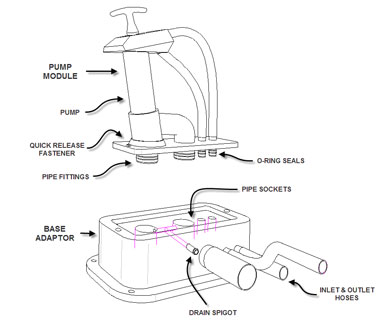

The Base Adaptor includes a drainage solution for the wastewater in/out pipes which enables clean and easy removal of excess fluid left in the sockets when a used Pump module is removed from the Base Adaptor. There is no need for taps, drainage starts when the cartridge is partially unplugged and the Pump module pipe o-rings rise in the Base Adaptor pipe sockets exposing orifices on the side of the waste water pipe sockets that connect to a single, small spigot. A disposable bottle is used to capture the excess fluid.

Replacement Procedure

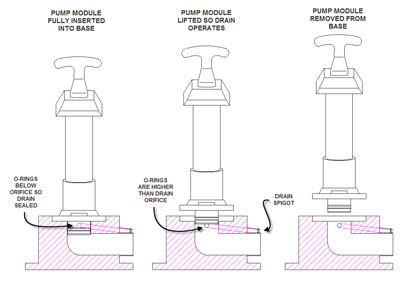

- Turn off the inlet sea cock

- Turn off the outlet sea cock

- Fit the disposable drain bottle (provided in the replacement Pump module kit) to the drain spigot.

- Using a coin turn each of the quarter turn fasteners (2) on the top of the Pump module to the left until the red indicator shows in the viewing hole on the fastener.

- Slowly lift the pump module. If fluid starts to flow into the drain bottle, halt lifting the cartridge until the flow stops. Once the flow stops, continue to lift the cartridge until the pipe fittings on the bottom of cartridge are approximately 2” above the Base Adaptor.

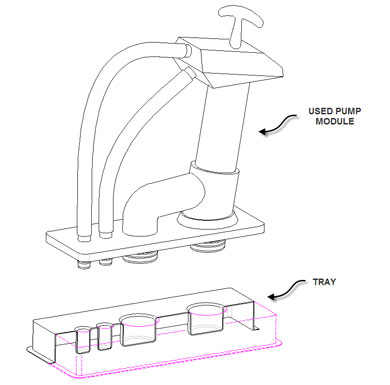

- Slip the disposal tray (provided in the replacement Pump module kit) under the used pump module and insert the used Pump module pipe fittings into the disposal tray.

- Place the used Pump module and tray in the plastic bag provided in the kit.

- Remove the drain bottle from the side of the Base Adaptor and seal with the cap provided. Place the drain bottle in the plastic bag, seal the bag and dispose of it in an environmentally friendly manner.

- Insert the pipe fittings of the new Pump module into the pipe sockets on top of the Base Adaptor, and push the Pump module down until its bottom surface is hard against the top of the Base Adaptor.

- Using a coin or flat blade screwdriver turn each of the quarter turn fasteners (2) on the top of the Pump module to the right until the green indicator shows in the viewing hole on the fastener.

- Turn on the outlet sea cock.

- Turn on the inlet sea cock.

- Check for any leaks.

Toilet Conversion Kit

The items included in the conversion kit to make a toilet compatible with the Pump module are:

- 1x Base Adaptor with mounting bolts

- 1x Seals

- 1x User Instructions

Replacement Pump Module Kit

The replacement Pump module Kit includes the following items :

- 1x Pump module

- 1x Disposable Drain Bottle

- 1x Disposal Tray

- 1x Disposal Bag

- 1x User Instructions

The only tool required for the replacement process is a flat bladed screwdriver or coin.

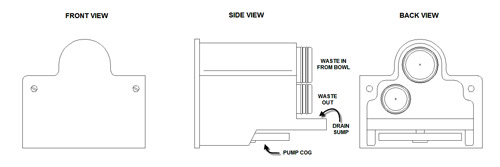

Electric Toilet Pump Module Technical Implementation Overview

The objective of the proposed technical solution is an electric powered toilet pump that can be replaced without tools.

The implementation is based on a universal, disposable Pump Module - a complete waste pump (without motor) - that plugs and latches into a permanently installed Base Adaptor. A Manufacturer might decide to supply Base Adaptor kits to fit various popular marine toilets on the market or sell it only for its own brands. Once the Base Adaptor is fitted, the toilet is ready to use with universal, disposable Pump Modules.

The description below is based on the popular Jabsco electric toilet assembly (eg. model 37245 series). The Base Adaptor accepts the standard Jabsco toilet bowl and electric motor.

Pump Module

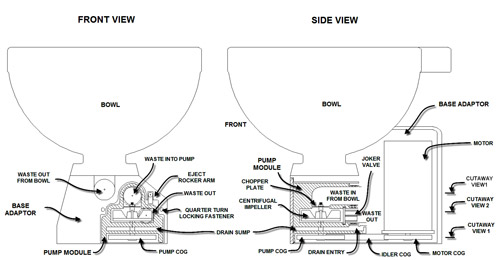

The removable Pump Module includes the standard Jabsco centrifugal impeller, chopper plate and joker valve.

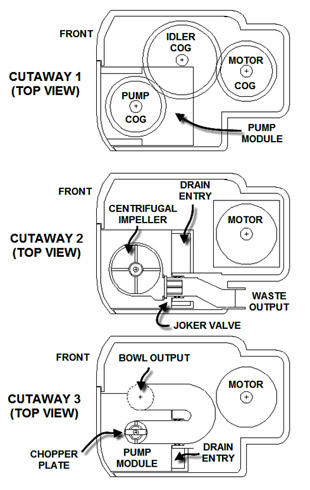

The centrifugal impeller and the chopper plate are mounted on a vertical shaft which is driven by the Pump Cog. This toothed Pump Cog is located horizontally underneath the Pump Module and is driven by the Idler Cog in the Base Adaptor.

The Pump Module has two pipe fittings extending out of the back of the module : wastewater in and wastewater out. Each pipe fitting includes two o-rings to provide a double seal when the Pump Module is inserted into the Base Adaptor. The pipe o-rings are mounted on the Pump Module rather than the Base Adaptor so that new, replacement seals between the adaptors are provided every time the module is replaced.

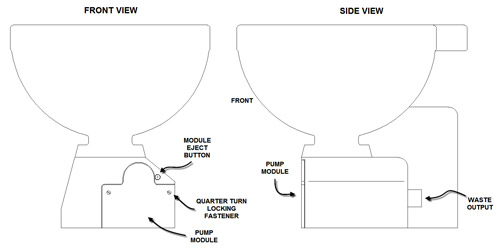

The Pump Module includes two quarter turn, quick release fasteners to securely fasten the Pump Module into the Base Adaptor. A coin or screw driver is used to release these fasteners to avoid accidental release of the Pump Module from the base. A green “engaged” or a red “disengaged” indicator is displayed by the fasteners to give a clear indication that the Pump Module is installed and latched correctly. When replacing a used Pump Module, the Eject toggle lever on the front of the Pump Module is used to eject the module out of the Base Adaptor after the fasteners have been released.

The Pump Module includes a drainage solution for the wastewater in/out pipes which enables clean and easy removal of the module without spilling excess fluid left in the sockets and pipes when a used Pump Module is removed from the Base Adaptor. The Pump Module includes an integral Drain Sump which will catch and store any excess fluid release when the Pump Module is removed.

Base Adaptor

The Base Adaptor includes a redesigned wastewater feed coming from below the bowl. The Base Adaptor and the wastewater feed don’t include any moving parts, valves or seals, so do not need to be replaced or maintained. The only maintenance item in the Base Adaptor is the standard electric motor which can be easily replaced without removing the Pump Module or any hoses.

The Pump Cog is located on the bottom of the electric motor and is used to drive the pump. This toothed Pump Cog drives the adjacent, spring loaded Idler Cog which, in turn, drives the Pump Cog in the Pump Module causing the centrifugal impeller and chopper plate to rotate in the pump section.

The Base Adaptor has two pipe sockets inside which accept the two pipes protruding from the back of the Pump Module. Each pipe socket includes a bevelled entry to guide the Pump Module pipes and their o-rings smoothly into the Base Adaptor.

The Base Adaptor provides the following connections for the pipe fittings from the Pump Module:

- Wastewater In: connects to the toilet bowl

- Wastewater In: connects to the toilet bowl

Replacement Procedure

- Turn off the inlet sea cock.

- Turn off the outlet sea cock.

- Using a coin turn each of the quarter turn fasteners (2) on the front of the Pump Module to the left until the red indicator shows in the viewing hole on the fastener.

- Push the Eject button on the front of the Pump Module.

- Slowly slide the Pump Module forward out of the Base Adaptor.

- Place the used Pump Module in the plastic bag provided in the kit.

- Insert the new Pump Module into the front of the Base Adaptor and slide it in until the pipes on the back of the Pump Module engage with pipe sockets inside the Base Adaptor, then push the Pump Module in until its front surface is flush with the front of the Base Adaptor.

- Using a coin or flat blade screwdriver turn each of the quarter turn fasteners (2) on the front of the Pump Module to the right until the green indicator shows in the viewing hole on the fastener.

- Turn on the outlet sea cock.

- Turn on the inlet sea cock.

- Check for any leaks.

Replacement Pump Cartridge Kit

The replacement Pump Cartridge Kit includes the following items:

- 1x Pump Cartridge

- 1x Disposal Bag

- 1x User Instructions

Tools Required for Replacement

The only tool required for the replacement process is a flat bladed screwdriver or coin.